low temperature compression test|Low temperature in : chain store Compression testing is a type of mechanical testing that involves applying a compressive force to a material and measuring its response. The compressive force tends to reduce the size of the material, and the test is designed to . web5 de ago. de 2023 · Por Agência Kalima. 5 de agosto de 2023, 16:27h. Descubra como saber se ganhou na Tele Sena e conheça todas as formas de ser premiado, incluindo prêmios de até R$ 1 milhão. Saiba como conferir os resultados de forma simples e fácil! Como saber se ganhou na Tele Sena é uma dúvida bastante comum e que muitas .

{plog:ftitle_list}

There’s no need to dig up those old storybooks because the White Rabbit slot machine by Big Time Gamingis here to transport you back in time. This game takes you to Wonderland, right to the Caterpillar’s . Ver mais

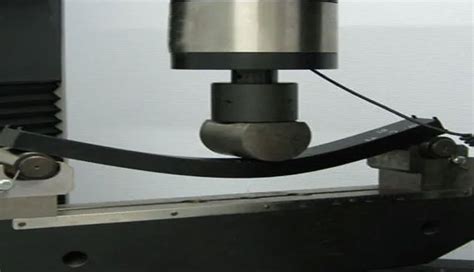

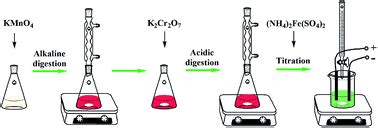

Parker tests compounds at low temperatures using ASTM D1329, also called the TR-10 method. For O-rings and other compression seals, the TR-10 value per ASTM D1329 provides a better means of approximating the low temperature .Compression testing is a type of mechanical testing that involves applying a compressive force to a material and measuring its response. The compressive force tends to reduce the size of the material, and the test is designed to .

Low-Temperature Testing capabilities at ARDL include low-temperature bend, brittleness, compression set, retraction, Shore A durometer, torsional stiffness and Youngs Modulus at .

This article provides a discussion on the mechanical properties of metals, ceramics, and polymers and fiber-reinforced polymer composites at low temperatures. It reviews the factors to be .The low-temperature properties of cork rubber materials are important when used in applications in colder climates, or, in environments that have low temperature requirements. There are a .

The chapter describes the factors that influence the selection of tensile testing procedures for low-temperature evaluation, along with a comparison of tensile and compression tests. It covers . Composite materials undergo a compressive strength test, also known as a compression test, to measure their response when subjected to force. The methods can vary .

Tension and Compression Testing at Low Temperatures

Compression set at low temperature: IS0 1653. The test piece, normally a cylinder, 29 mm in diameter and mm high, is compressed to 75% of its original height between two plates .

The following test methods can be used to assess the suitability of a compound in low temperature applications. We break these out into more detail throughout the rest of this blog post. Brittleness test: ASTM D2137; ISO 812; . We report results of uniaxial compression testing of 1 µm diameter single crystalline Fe pillars at 198 K and room temperature. A cooling system interfaced with an .

In order to study the macroscopic mechanical properties and meso damage mechanism of solid fuel hydroxy-terminated polybutadiene (HTPB) propellant under low temperature and dynamic biaxial compression loading, the INSTRON high strain rate hydraulic testing machine was used to carry out dynamic biaxial compression test of HTPB propellant .

It reviews the factors to be considered in tensile and compression testing of these materials. The article details the equipment used for low-temperature tensile and compression tests with illustrations. It concludes with a discussion on the various test methods and their ASTM standard for compression and tension testing.

Technical bulletin T&D low temperature testing

Performing compression set at low temperatures without having to open the deep freezer and influence the compression set result has always been a problem.By .

There are multiple test methods that are used in the industry; ISO 815 and ASTM D395 are the most commonly used. However, there are other test methods that may be used depending on the application and specifics on what the engineer is trying to achieve, as in the case of using ISO 1653 for testing compression set at low temperatures.The compression set was determined according to ASTM D395 Method B. The following temperatures were used to study the effect of temperature on the compression set: Compression Set Temperatures: 25˚C, 50˚C, 70˚C and 85˚C To determine the effect of % deflection, the following levels were used: % Deflection: 3%, 5%, 10% and 25%

This advanced Low Temperature Compression Set Testing Machine is used for the determination of the compression set characteristics of vulcanized and thermoplastic rubbers at low temperatures. Method 2 of ISO 815 standard uses a specified testing device, allowing to measure and record the test piece thickness during recovery. Due to the load applied during . Engine CompressionAtmospheric pressure at sea level is approximately 14.7 psi.A 9:1 compression ratio cylinder is compressing the air and fuel mixture to about 132 psi at sea level (9x14.7=132.3 .

Testing the engine compression on your Chevrolet or GMC 4.8L, 5.0L, or 6.0L engine is not hard to do. A compression test will help you to determine the health of your engine by measuring the pressure of the air that gets compressed by the .Low temperature compression set test system Optional hood (ET 03.02) for LTCS in case of condensation problems. Can be combined with an air dryer. We can supply air dryers with either -40 °C or -70 °C dewpoints (ET 08-xx). An alternative is to use desiccant in the hood. Low temperatures compression set (LTCS) software, EC 10.

The low-temperature compression behaviors of concrete-filled steel tube columns (CFSTs) in different shapes were studied by Yan et al. . The failure modes of typical SSTs after the low-temperature compression test are shown in Fig. 6. It clearly shows that two types of failure modes existed in these specimens, i.e., local buckling (LB) and . Doing a compression test, is a good way to measure the condition of the rings, cylinders, and valves. . Temperature; Worn camshaft lobes; High performance long duration profile camshafts; . Your compression, is low on the first stroke. And, compression usually does not build up, on the following strokes. .The chapter describes the factors that influence the selection of tensile testing procedures for low-temperature evaluation, along with a comparison of tensile and compression tests. It covers the parameters and standards related to low-temperature tensile testing. The chapter discusses the factors involved in controlling test temperature. Carry Out a Compression Test. To find out which cylinders have low compression, you’ll need to carry out a compression test. You’ll need a compression gauge, some tools, and a little mechanical knowledge to do this. Step 1. Remove the fuel pump and fuel injector fuses. This stops the engine from injecting fuel into the cylinders when .

Review’ of Test Methods for Determination of Low

If the compression test results indicate low compression and the cylinder leakage test confirms significant leakage, it suggests that the engine’s cylinders are not sealing properly. . Before starting the compression test, it is crucial to warm up the engine to its normal operating temperature. This allows for better fuel combustion and . The low-temperature tension test results show that most of the tensile fracture of SS samples took place at their middle regions within the gauging scope at varying temperatures of −80 ∼ 20℃. Fig. 3 provides the failure modes after tension tests at ambient and low temperature for SS samples of each thickness and shape.

Fig. 8 shows the comparison of force-displacement curves of CFST columns between simulation and test results at different temperatures. It can be seen that the numerical curves of circular and square CFST columns conform to the test results both at ambient temperature and low temperatures. . Low-temperature compression behaviour of square .Compression set values generally increase with increased temperature and time. For O-rings the minimum squeeze should be about .007 inch. (0,175mm). The reason is that with a very light squeeze almost all elastomers quickly take 100% compression set. A good compression set resistant compound can be distinguished from a poor one only The temperature of the specimen was allowed to equilibrate with the chamber for 30 min prior to starting the compression test. . a glassy regime at low temperatures with minimal negative slope, (II) a transition regime with a . Walley S, Field J (1994) Strain rate sensitivity of polymers in compression from low to high rates. DYMAT J 1(3 . The low-temperature compression tests showed that the CFUTs failed in concrete crushing, outward local buckling and weld fracture at the corner of Q960 square UHSS tube. . Test results revealed that decreasing low temperature significantly improved the strength of SS especially the ultimate strength, but reduced its ductility. Twenty SSSSTCs .

A complete Low Temperature Compression Set test system requires the following components: • EV 09 – Test rig adapted for Low Temperature Compression Set. • ET 03 – Low temperature laboratory freezer (-10 to -45 °C). • ET 03.01‑x – conversion kit for the freezer (available for 4 or 6 rigs). • ED 04 – Computer (Windows). Finally, test results from the snap test should be about, 80% of the cranking (static) compression test. Engine Compression Gauge Showing High Compression Engine Compression Gauge Showing Low Compression. A Low, Snap Test Reading. If a snap reading is low (much less than 80% of cranking compression), look for air intake problems. . Fig. 3 plots the low-temperature compression test setup for CFUTs. As shown in Fig. 3 (a), each CFUT was cooled to the specified T level in a refrigerator for at least 48 h as required by GB51081 [43]. After that, the CFUT was moved into the frame of a 1500-ton testing machine with its bottom end directly put on the support. Testing for Compression Set. Several test methods exist for quantifying the compression set of elastomers. Two common test methods are ASTM D-395 and ASTM D-1414. Both test methods use the same test apparatus, but different test specimens. . Shown below is the typical test temperature for polymers as listed in the ASTM D2000. It is very .

air permeability testing consultants

What is a Compression Test? A compression test measures the pressure of the air-fuel mixture in the engine’s cylinders. High compression readings indicate that the engine is in good health, while low readings can point to issues like worn piston rings, bad valves, or even a blown head gasket. Hot Compression Test The warm forming of Ti–6Al–4V alloys at relatively low temperatures (600–800 °C) is attractive because it affords microstructural superplasticity at high strain rates and provides ultrafine-grained equiaxed microstructures. . The temperature increase during the cylinder compression test was not compensated because it can be subtracted .

Fig. 3 shows the low-temperature compression-test setup of CFSSSTs at low temperatures. Download: Download high-res image (506KB) Download: Download full-size image; Fig. 3. Compression-test setup on CFSSTs at different T. Each CFSSST was firstly stored in a cold storage for at least 48 h following specifications in GB51081–2015 [43]. The result shows that the compression performance of rubber seal strip is sensitive to the extreme low temperature, and it is prone to low-temperature failure. The simulation results in this paper can provide an important reference for the subsequent low-temperature environmental test, so as to more comprehensively analyse the low-temperature .

air permeability testing consultant

WEBVitorlát fel és indulás! A Columbus™ deluxe játékban a 7 világtengert és egy nyerési esélyekkel teli új világot kell meghódítanod! 5 tárcsán 10 nyerővonal vár rád a normál játékban, a bónuszjátékban pedig tengeri felfedezőútra indulhatsz, ahol tekintélyes twist-eket hódíthatsz meg!. A játék célja, hogy a nyerővonal mentén 5 azonos szimbólumot .

low temperature compression test|Low temperature in